-

当前位置 > 首页 - 正文

-

What are the technological processes of aluminium alloy die casting dies?

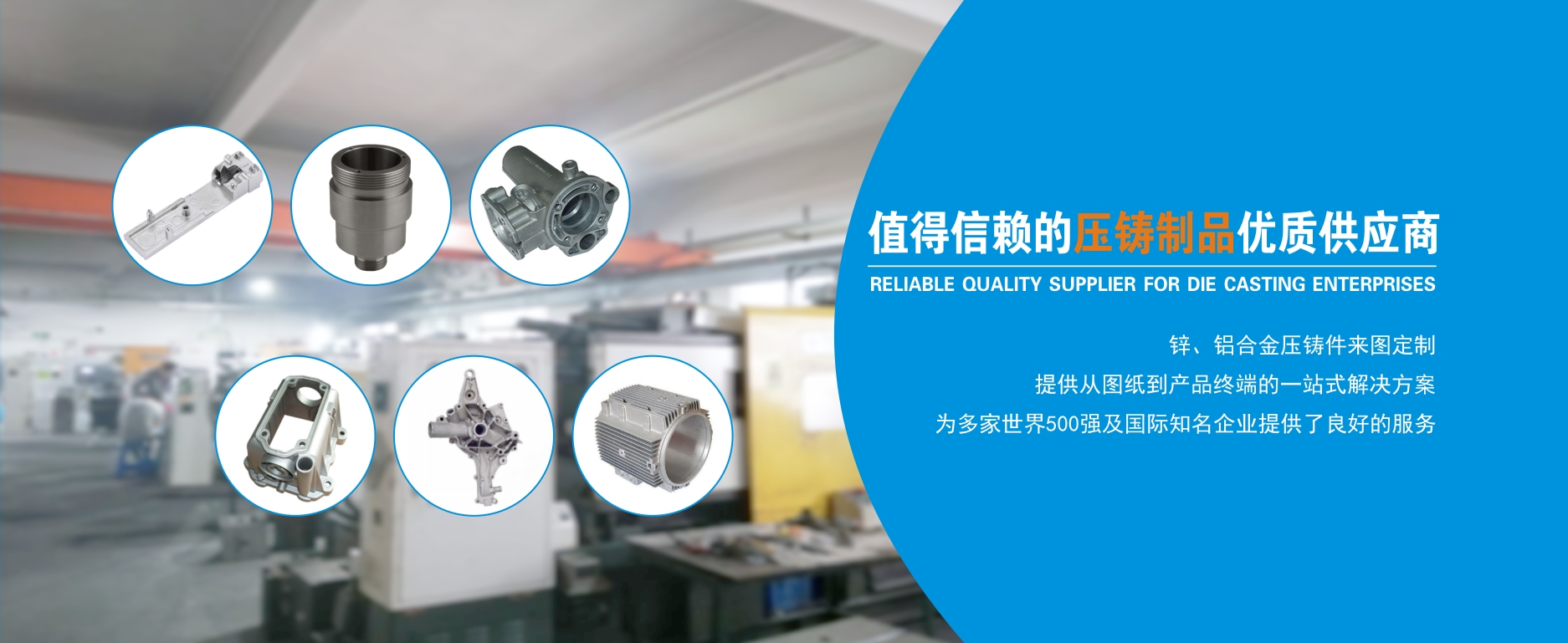

发布时间:2019/6/4 1:05:43 | 信息来源:Dongguan zhongding precision mould co. LTDDongguan Zhongding Precision Die Co., Ltd. is an enterprise specializing in the design and production of zinc alloy die-casting dies, aluminum alloy die-casting dies, magnesium alloy die-casting dies and die-casting products processing. It provides one-stop service from materials, dies, die-casting, post-processing and surface treatment. Provide professional die casting die and product processing services for many top 500 enterprises in the world. Discuss the manufacturing process of die casting die for aluminium alloy.

Aluminum die-casting die design: divided into product splitting, runner design, slider, ejector, exhaust, slag discharge design and so on; this requires full experience of the die designer and familiarity with the product, so that the designed aluminum die-casting die can have a good effect both in service life and in die-casting products.

Design drawings: Aluminum die-casting die parts and accessories are drawn one by one, first of all, 3D drawings, secondly, 2D drawings. After drawing, first, design audits, secondly, the head of the die Department and the corresponding project engineers, business drawings, to ensure the smooth production and production of aluminum die-casting die.

Aluminum die casting die processing: die processing is divided into die frame processing, die kernel (core) processing, pin, slider and other parts processing, in addition to the need to use spark machine, milling machine, grinder, CNC, heat treatment and other die manufacturing equipment for processing;

Aluminum die-casting die assembly: this plate needs to be completed smoothly in front of the process, all kinds of accessories in place, generally by the fitter responsible for this set of molds, which requires the fitter to be very familiar with the mold, and have some experience, know the drawings, assembly technology, understand various die-making machinery, otherwise in the case of assembly can not be dealt with independently, The experienced fitter often can assemble a set of moulds independently facing various problems.

Solid die of aluminium die-casting die: When the die assembly is completed, the corresponding schedule of production and solid die needs to be adjusted by the die-casting machine. T1 die test. Here, the head of the die-casting forming department and the fitter, engineer and professional assistant responsible for the die set are needed to complete. When the product of the test die is to be cooled, the quality inspection is carried out.

Product inspection after die testing: This process requires quality personnel, engineers and businesses to complete together. If the product accuracy, appearance and structure meet the design parameters of the die and are considered to be qualified, it can be sent to the customer for inspection and acceptance. If not, it requires the die design, the head of the die Department and the fitter to discuss the improvement and solutions until the product closes. Up till now.上一篇:无信息

专注多向锻压铸、真空压铸技术25年

全国服务热线

13926850545

联系人:叶先生

联系人:叶先生